The role of pressure sensors in the automotive industry

Pressure sensors play a crucial role in the automotive industry and are widely used in multiple systems to ensure the safe and efficient operation of vehicles. Here are some of the main application scenarios:

Engine Management System

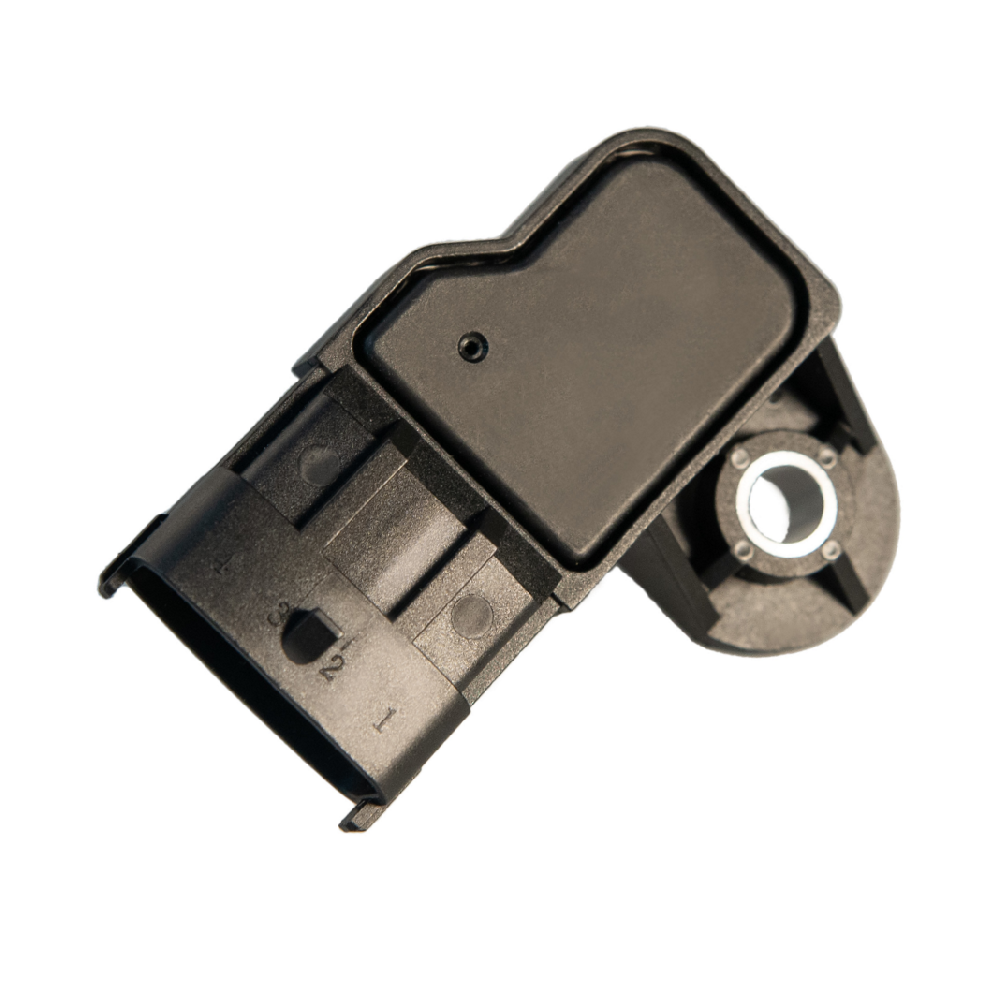

- Intake Manifold Pressure Sensor

The intake manifold pressure sensor (MAP sensor) is used to measure the absolute pressure inside the intake manifold. The engine control unit (ECU) uses the pressure data provided by this sensor, combined with information such as engine speed, to accurately calculate the amount of air entering the engine. This allows for precise control of the air - fuel ratio.

For example, under different operating conditions such as idling, accelerating, and decelerating, the ECU adjusts the fuel injection strategy in real - time based on the data from the MAP sensor. This ensures that the engine maintains good power performance and fuel economy in all operating conditions. If the MAP sensor malfunctions, it may lead to reduced engine power, increased fuel consumption, and unstable idling.

- Fuel Pressure Sensor

The fuel pressure sensor is installed on the fuel line to monitor the pressure of the fuel system. It ensures that fuel is delivered to the engine's fuel injectors at a stable pressure, guaranteeing the accuracy and consistency of fuel injection.

In modern automotive fuel injection systems, precise fuel pressure control is crucial for engine performance. When the fuel pressure is too low, the fuel injectors may not spray enough fuel, resulting in insufficient engine power. Conversely, if the fuel pressure is too high, the injectors may over - spray fuel, leading to fuel waste and excessive emissions. The fuel pressure sensor feeds back the fuel pressure information to the ECU, which can then adjust the operation of the fuel pump to maintain the fuel pressure within the normal range.

Braking System - Brake Fluid Pressure Sensor

The brake fluid pressure sensor is used to monitor the pressure of the brake fluid in the braking system. It plays a key role in active safety systems such as the Electronic Stability Program (ESP) and the Anti - lock Braking System (ABS).

When the driver presses the brake pedal, the brake fluid pressure sensor detects the change in brake fluid pressure in real - time and sends the signal to the ECU. The ECU determines the braking state of the vehicle based on this information and controls the braking pressure of each wheel to prevent wheel lock - up, improving braking safety and stability. For example, during emergency braking, the ESP system can independently control the braking of each wheel according to the data from the brake fluid pressure sensor, keeping the vehicle stable and preventing skidding and tail - whipping. - Tire Pressure Monitoring System (TPMS)

TPMS is a system that directly or indirectly monitors tire pressure. Direct - type TPMS usually uses pressure sensors to measure the air pressure of each tire in real - time.

The pressure sensors are installed inside the tires or on the valve stems and wirelessly transmit the tire pressure information to the in - vehicle receiver. When the tire pressure is too low or too high, the system will issue an alarm in a timely manner to remind the driver to take appropriate measures. Maintaining normal tire pressure not only improves driving safety but also reduces tire wear and enhances fuel economy.

Suspension System

In some high - end automotive active suspension systems, pressure sensors are used to monitor the pressure changes in the hydraulic or pneumatic components of the suspension system.

By obtaining real - time pressure information from the pressure sensors, the ECU can automatically adjust the stiffness and height of the suspension according to the vehicle's driving conditions (such as vehicle speed and road surface conditions), providing better ride comfort and handling stability. For example, at high speeds, the suspension system can automatically adjust to a stiffer state based on the data from the pressure sensors to improve vehicle stability. When passing over bumpy roads, the suspension system can adjust to a softer state to reduce body vibrations.

Air Conditioning System

The pressure sensors in the automotive air - conditioning system are used to monitor the pressure of the refrigerant. They ensure that the air - conditioning system operates within the normal pressure range, improving cooling efficiency and protecting key components such as the compressor.

When the refrigerant pressure is too high or too low, the pressure sensor sends a signal to the air - conditioning control system, which then takes appropriate measures such as adjusting the operating state of the compressor and controlling the opening of the expansion valve. For example, when the refrigerant pressure is too high, the system may reduce the compressor's speed to prevent damage due to overloading. When the refrigerant pressure is too low, the system may stop the compressor to avoid dry - running.

In summary, pressure sensors are widely used in multiple key systems in the automotive industry, including the engine, braking, suspension, and air - conditioning systems. They are of great significance for improving vehicle performance, safety, and comfort. With the continuous development of automotive technology, the accuracy and reliability of pressure sensors are also constantly improving, and they will play an even more important role in future vehicles.